Technical specifications of original Comler generator sets:

| Model | Brand | Engine Model | Engine Normal Power (KW) | Speed Control | Engine Brand | Rated voltage (V) | Rated current (A) | Power factor | Frequency (HZ) | Speed (r/min) | Dimensions (mm) | Weight (KG) |

| COMLER10KW | COMLER | COMLER4G401 | 16 | High pressure common rail | COMLER | 400/230 | 18 | 0.8 | 50 | 1500 | 1400*600*1005 | 470 |

| COMLER15KW | COMLER | COMLER4G401.5 | 22 | High pressure common rail | COMLER | 400/230 | 27.1 | 0.8 | 50 | 1500 | 1400*600*1005 | 475 |

| COMLER20KW | COMLER | COMLER4G402 | 27 | High pressure common rail | COMLER | 400/230 | 36.1 | 0.8 | 50 | 1500 | 1400*600*1005 | 480 |

| COMLER30KW | COMLER | COMLER4G403 | 36 | High pressure common rail | COMLER | 400/230 | 54.1 | 0.8 | 50 | 1500 | 1440*600*1050 | 500 |

| COMLER40KW | COMLER | COMLER4G304 | 49 | High pressure common rail | COMLER | 400/230 | 72.2 | 0.8 | 50 | 1500 | 1700*750*1180 | 950 |

| COMLER50KW | COMLER | COMLER4G305 | 58 | High pressure common rail | COMLER | 400/230 | 90.2 | 0.8 | 50 | 1500 | 1700*750*1180 | 1050 |

| COMLER70KW | COMLER | COMLER4G307 | 78 | High pressure common rail | COMLER | 400/230 | 126.3 | 0.8 | 50 | 1500 | 1900*800*1420 | 1250 |

| COMLER80KW | COMLER | COMLER4G308 | 95 | High pressure common rail | COMLER | 400/230 | 144.3 | 0.8 | 50 | 1500 | 1900*800*1420 | 1280 |

| COMLER100KW | COMLER | COMLER4G31 | 125 | High pressure common rail | COMLER | 400/230 | 180.4 | 0.8 | 50 | 1500 | 2050*800*1450 | 1350 |

| COMLER120KW | COMLER | COMLER6G31.2 | 140 | High pressure common rail | COMLER | 400/230 | 216.5 | 0.8 | 50 | 1500 | 2600*900*1550 | 1600 |

| COMLER150KW | COMLER | COMLER6G31.5 | 186 | High pressure common rail | COMLER | 400/230 | 270.6 | 0.8 | 50 | 1500 | 2600*900*1550 | 1800 |

| COMLER170KW | COMLER | COMLER6G31.7 | 186 | High pressure common rail | COMLER | 400/230 | 306.7 | 0.8 | 50 | 1500 | 2600*900*1550 | 2030 |

| COMLER180KW | COMLER | COMLER6G31.8 | 208 | High pressure common rail | COMLER | 400/230 | 324.8 | 0.8 | 50 | 1500 | 2600*960*1650 | 2300 |

| COMLER200KW | COMLER | COMLER6G32 | 230 | High pressure common rail | COMLER | 400/230 | 360.9 | 0.8 | 50 | 1500 | 2600*960*1650 | 2600 |

| COMLER230KW | COMLER | COMLER6G32.3 | 255 | High pressure common rail | COMLER | 400/230 | 415 | 0.8 | 50 | 1500 | 2600*960*1650 | 2800 |

| COMLER250KW | COMLER | COMLER6G32.5 | 307 | High pressure common rail | COMLER | 400/230 | 451.1 | 0.8 | 50 | 1500 | 3150*1140*1760 | 3100 |

| COMLER280KW | COMLER | COMLER6G32.8 | 307 | High pressure common rail | COMLER | 400/230 | 505.2 | 0.8 | 50 | 1500 | 3150*1140*1760 | 3200 |

| COMLER300KW | COMLER | COMLER6G33 | 340 | High pressure common rail | COMLER | 400/230 | 541.3 | 0.8 | 50 | 1500 | 3150*1140*1760 | 3300 |

| COMLER320KW | COMLER | COMLER6G33.3 | 360 | High pressure common rail | COMLER | 400/230 | 577.4 | 0.8 | 50 | 1500 | 3150*1230*1760 | 3500 |

| COMLER360KW | COMLER | COMLER6G33.6 | 401 | High pressure common rail | COMLER | 400/230 | 649.5 | 0.8 | 50 | 1500 | 3150*1230*1760 | 3600 |

| COMLER400KW | COMLER | COMLER6G34 | 450 | High pressure common rail | COMLER | 400/230 | 721.7 | 0.8 | 50 | 1500 | 3150*1230*1760 | 3800 |

| COMLER450KW | COMLER | COMLER6G34.5 | 520 | High pressure common rail | COMLER | 400/230 | 811.9 | 0.8 | 50 | 1500 | 3800*1240*2356 | 5050 |

| COMLER500KW | COMLER | COMLER6G35 | 572 | High pressure common rail | COMLER | 400/230 | 902.1 | 0.8 | 50 | 1500 | 3800*1240*2356 | 5200 |

| COMLER550KW | COMLER | COMLER6G35.5 | 622 | High pressure common rail | COMLER | 400/230 | 992.3 | 0.8 | 50 | 1500 | 3800*1240*2356 | 5400 |

| COMLER600KW | COMLER | COMLER6G36 | 685 | High pressure common rail | COMLER | 400/230 | 1082.6 | 0.8 | 50 | 1500 | 3800*1240*2356 | 5600 |

| COMLER660KW | COMLER | COMLER6G36.6 | 728 | High pressure common rail | COMLER | 400/230 | 1190.8 | 0.8 | 50 | 1500 | 3800*1240*2356 | 6050 |

| COMLER730KW | COMLER | COMLER6G37.3 | 820 | High pressure common rail | COMLER | 400/230 | 1317.1 | 0.8 | 50 | 1500 | 4100*1800*2450 | 7500 |

| COMLER800KW | COMLER | COMLER6G38 | 880 | High pressure common rail | COMLER | 400/230 | 1443.4 | 0.8 | 50 | 1500 | 4100*1800*2450 | 8200 |

| COMLER900KW | COMLER | COMLER6G39D | 1018 | Electronic control unit pump | COMLER | 400/230 | 1623.8 | 0.8 | 50 | 1500 | 4450*1800*2430 | 10500 |

| COMLER1000KW | COMLER | COMLER6G310D | 1118 | Electronic control unit pump | COMLER | 400/230 | 1804.3 | 0.8 | 50 | 1500 | 4450*1850*2430 | 11000 |

| COMLER1100KW | COMLER | COMLERG311D | 1230 | Electronic control unit pump | COMLER | 400/230 | 1984.7 | 0.8 | 50 | 1500 | 4450*1850*2430 | 11600 |

| COMLER1200KW | COMLER | COMLER12G312 | 1420 | High pressure common rail | COMLER | 400/230 | 2165.1 | 0.8 | 50 | 1500 | 5250*2320*2834 | 13800 |

| COMLER1350KW | COMLER | COMLER12G313.5 | 1560 | High pressure common rail | COMLER | 400/230 | 2435.8 | 0.8 | 50 | 1500 | 5250*2320*2834 | 14000 |

| COMLER1500KW | COMLER | COMLER12G315 | 1720 | High pressure common rail | COMLER | 400/230 | 2706.4 | 0.8 | 50 | 1500 | 5400*2320*2834 | 16000 |

| COMLER1600KW | COMLER | COMLER12G316 | 1850 | High pressure common rail | COMLER | 400/230 | 2886.8 | 0.8 | 50 | 1500 | 5400*2320*2834 | 16500 |

| COMLER1800KW | COMLER | COMLER12G318 | 2010 | High pressure common rail | COMLER | 400/230 | 3247.7 | 0.8 | 50 | 1500 | 5500*2320*2900 | 18500 |

| COMLER2000KW | COMLER | COMLER16G320 | 2250 | High pressure common rail | COMLER | 400/230 | 3608.5 | 0.8 | 50 | 1500 | 6500*2350*2845 | 21800 |

| COMLER2200KW | COMLER | COMLER16G622 | 2510 | High pressure common rail | COMLER | 400/230 | 3969.4 | 0.8 | 50 | 1500 | 6500*2350*2845 | 22800 |

| COMLER2400KW | COMLER | COMLER16G324 | 2680 | High pressure common rail | COMLER | 400/230 | 4330.3 | 0.8 | 50 | 1500 | 6500*2350*2845 | 24800 |

| COMLER2500KW | COMLER | COMLER16G325 | 2773 | High pressure common rail | COMLER | 400/230 | 4510.7 | 0.8 | 50 | 1500 | 6500*2350*2845 | 25800 |

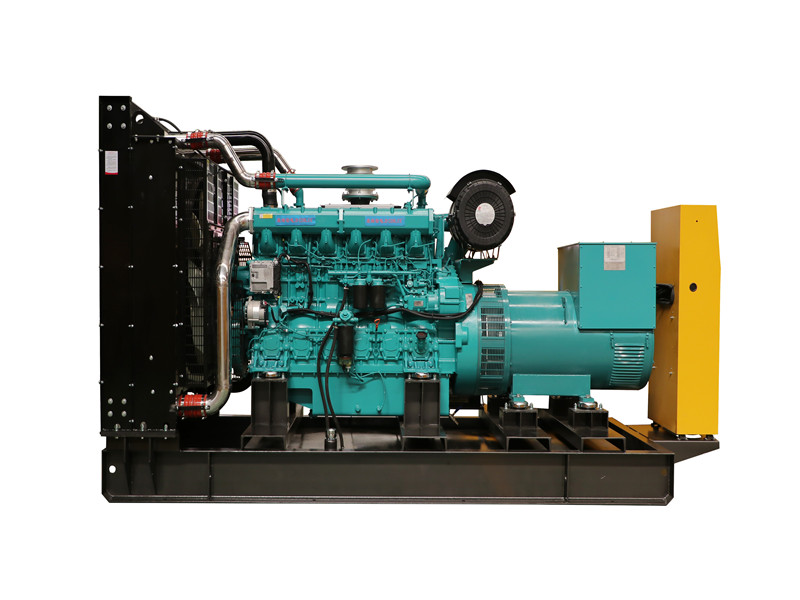

Overview of COMER Original Generator Set

The original COMLER generator set adopts a full range of COMLER engines, generators, intelligent control systems, and 50°C radiators. With superior integrated design, production, assembly, and a complete industry chain, it eliminates the drawbacks of assembled units, delivering better performance. It is the ideal power supply solution for customers requiring prime power, offering more reliable service. The heavy-duty design ensures high performance, making it particularly suitable for industries with high-frequency usage. As a prestigious international brand, COMLER provides superior service, continuously creating value for customers.

COMLER Advanced Technological Advantages

The original COMLER generator set is designed with advanced European and American technologies, including high-pressure common rail fuel injection, twin-turbocharging systems, and four-valve technology. It excels in heavy-duty operating conditions, offering greater convenience, higher efficiency, and lower fuel consumption (192g/kWh)—3-5% lower than other power range products—reducing operational costs. It also features a longer service life, low-carbon environmental benefits, and cutting-edge technology.

COMLER Performance Advantages

The original integrated unit boasts a high-performance heavy-duty design, making it ideal for high-frequency usage industries and various complex operating conditions. Its advantages are particularly evident in extreme environments, such as high altitudes (5,000 meters), ultra-low temperatures (-45°C), high temperatures (50°C), salt spray, and sudden load changes.

COMLER Reliability Advantages

Engine Reliability: The engine features a high-strength block with a rear-mounted gear chamber, curved surface design, and rationally distributed reinforcing ribs, ensuring superior strength, rigidity, and reliability. It delivers excellent NVH (Noise, Vibration, Harshness) response. With a one-cylinder-one-head design and a crankcase window for easier maintenance, it offers stronger load capacity, higher torque, and enhanced overall reliability.

COMLER Environmental Advantages

Emission Compliance: Advanced electronically controlled high-pressure common rail fuel injection technology meets G3 standards, aligning with international technology and current national emission regulations.

Silent Enclosure:Equipped with a 75dB environmentally friendly silent enclosure, ensuring compliance with national noise regulations.

COMLER Operational Advantages

Suitable for prime power, heavy-load, isolated power stations, high-altitude regions, deserts, harsh environments, military applications, data centers, petroleum, engineering, power plants, mining, and other industrial applications.

COMLER Service Advantages

The original COMLER generator set is backed by a global premium service network, ensuring prompt support in any region. It offers a comprehensive pre-sales, sales, after-sales, and maintenance-oriented service system.

With unified design and branding for the engine, generator, control system, and radiator, technical support is more reliable.

The warranty period is two years or 3,000 hours—twice the industry average—supported by over 3,000 service centers and COMLER’s global engineers, delivering high-quality power products and services that create value.

COMLER Brand Value Advantage

As a respected international brand, COMLER is committed to providing superior service and continuously creating value for customers, which is the core mission of COMLER Power. The brand contributes to advancing the overall technological development and progress of China's power industry.

鲁公网安备37083002370842号

鲁公网安备37083002370842号