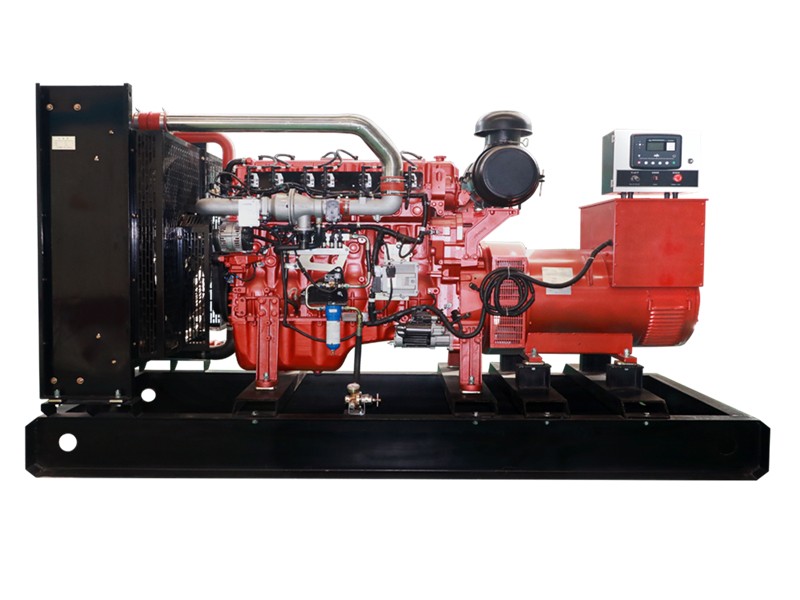

Comler Gas Generator Sets

Based on advanced European and American technologies, Comler gas generator sets are continuously innovated and developed. The produced gas generator sets feature superior performance, reliable quality, cleanliness, environmental friendliness, and low emissions, meeting the national excellent emission standards. They use low-cost gas fuels or circular economy fuels to provide an inexhaustible power supply. Comler Power has become the preferred power supply product for customers.

Comler gas generator sets include: natural gas generator sets, biogas generator sets, coalbed methane generator sets, bio-gas generator sets, liquefied petroleum gas generator sets, wellhead associated gas generator sets, straw gas generator sets, hydrogen generator sets, etc. These sets use combustible gases as fuel and adopt advanced technologies such as lean combustion, electronic ignition, and electronic speed regulation. They have the characteristics of sophisticated technology, compact structure, and convenient operation and maintenance. Major technical indicators, such as gas consumption rate, oil consumption rate, exhaust temperature, and vibration, have reached the international cutting-edge level. The products are maturely applied in oilfield associated gas, wellhead gas, coalbed methane power generation, and biomass gas power generation projects. The products are sold all over the country and exported to Southeast Asian, African countries and regions. With excellent performance and perfect service, the products have won high praise from users at home and abroad.

Functions and Features of COMLER Natural Gas Generator Sets

1.Clean and Environmentally Friendly: Compared with diesel oil, the use of natural gas can effectively reduce emissions, with NOx reduced by up to 40% and PM reduced to 0.

2.Low Cost and Wide Application: The gas consumption rate can be reduced to below 185g/kw.h, making it suitable for oil and gas fields or areas rich in gas. Multiple units can be paralleled and connected to the grid for self-use or external transmission.

3. Leading Speed Regulation Performance: Advanced electronic control technology is applied, combined with variable electronic throttle technology. The steady-state speed fluctuation rate is ≤ 1%, and the transient response speed is fast.

4. Excellent Starting Performance: The unit is equipped with an international brand ignition system, which has undergone strict testing and has a high starting success rate. It only takes 30 seconds from successful cold start to full-load operation.

5. Mature and Cutting-Edge Gas Control Technology

5.1Low-Pressure System

Adopting the internationally mainstream low-pressure intake premixing

technology, it has advantages such as modular design and ignition

self-diagnosis function.

5.2Medium and High-Pressure System

① Internationally advanced single-point injection technology: verified in mass market applications, with mature technology;

② Supercharged intercooled lean combustion technology: enables more efficient and clean combustion with good economy;

③ Electronic control supercharging technology: controls supercharging pressure to improve the responsiveness of the whole machine;

④ Oxygen sensor closed-loop control technology: precisely controls the air-fuel ratio to enhance the consistency and stability of the whole machine's performance;

⑤ Cylinder-independent ignition technology: each cylinder is independently ignited by an intelligent ignition coil, ensuring high reliability;

⑥ Fault diagnosis technology: complete fault diagnosis and protection strategies to protect the engine and promptly eliminate faults.

6. Island Operation: A local power grid constructed by combining multiple units can provide power guarantee for surrounding electrical equipment.

7. Paralleling and Grid Connection: High-performance brand controllers are adopted, which can be applied to the parallel operation of 2-32 generator sets. It features complete functions, high automation, reliable operation, convenient maintenance, and economical operation.

7.1Advantages of Paralleling: After multiple units are paralleled, the appropriate number of units can be automatically put into operation according to the load size to ensure that the units operate in good condition. This can reduce various losses, minimize unit failures, and bring significant economic benefits to enterprises.

7.2Stability Advantages: After paralleling, the power supply quality is high, and the voltage and frequency of electrical equipment are stable, which can withstand the impact of large loads on the generator. Each gas unit is equipped with a PMG system, which can effectively enhance the anti-interference ability of the unit.

7.3 Regulation Advantages: After paralleling, the units form an integrated power grid. With centralized control, power dispatching becomes convenient.

8. Advantages in Noise Reduction, Dust Prevention, and Rain Protection: The unit is equipped with a silent box, which uses special noise reduction and sound absorption materials to reduce mechanical noise to a greater extent, with the noise level reduced to below 75 decibels. It also has multiple functions such as rain protection, dust prevention, and heat preservation.

9.Easy Operation: Equipped with ATS and a high-performance intelligent electrical system, the unit can automatically start and stop, automatically switch between commercial power and generator power, and automatically monitor the unit's operating status without manual on-duty.

10. Remote Management: The Comler intelligent interconnection service system enables all-weather remote management of the generator set's standby and operating conditions, and automatically processes all data of the unit, making the unit more efficient.

鲁公网安备37083002370842号

鲁公网安备37083002370842号