Yuchai series (10kw-3000kw)Technical Specifications:

| Model | Brand | Engine Model | Engine Normal Power(KW) | Speed Control | Engine Brand | Rated voltage(V) | Rated current(A) | Power factor | Frequency (HZ) | Speed (r/min) | Dimensions (mm) | Weight (KG) |

| COMLER10KW | COMLER | YCDV254FHZ-25 | 20 | High pressure common rail | Yuchai | 400/230 | 18 | 0.8 | 50 | 1500 | 1500*660*1065 | 500 |

| COMLER15KW | COMLER | YCDV254FHZ-25 | 20 | High pressure common rail | Yuchai | 400/230 | 27.1 | 0.8 | 50 | 1500 | 1500*660*1065 | 520 |

| COMLER20KW | COMLER | YCDV254FHZ-35 | 25 | High pressure common rail | Yuchai | 400/230 | 36.1 | 0.8 | 50 | 1500 | 1500*660*1065 | 550 |

| COMLER25KW | COMLER | YCDV254FHZ-40 | 30 | High pressure common rail | Yuchai | 400/230 | 45.1 | 0.8 | 50 | 1500 | 1500*660*1065 | 600 |

| COMLER30KW | COMLER | YCDV254FHZ-50 | 36.8 | High pressure common rail | Yuchai | 400/230 | 54.1 | 0.8 | 50 | 1500 | 1500*660*1065 | 620 |

| COMLER40KW | COMLER | YCD4V33H6-75 | 50 | High pressure common rail | Yuchai | 400/230 | 72.2 | 0.8 | 50 | 1500 | 1500*660*1065 | 650 |

| COMLER50KW | COMLER | YC4D90-D34 | 60 | High pressure common rail | Yuchai | 400/230 | 90.2 | 0.8 | 50 | 1500 | 1900*800*1210 | 850 |

| COMLER60KW | COMLER | YC4D105-D34 | 70 | High pressure common rail | Yuchai | 400/230 | 108.3 | 0.8 | 50 | 1500 | 1900*800*1210 | 900 |

| COMLER90KW | COMLER | YC4D140-D31 | 100 | High pressure common rail | Yuchai | 400/230 | 162.4 | 0.8 | 50 | 1500 | 1960*800*1350 | 950 |

| COMLER100KW | COMLER | YC4A165-D30 | 110 | High pressure common rail | Yuchai | 400/230 | 180.4 | 0.8 | 50 | 1500 | 2180*800*1360 | 1050 |

| COMLER110KW | COMLER | YC4A190-D30 | 125 | High pressure common rail | Yuchai | 400/230 | 198.5 | 0.8 | 50 | 1500 | 2180*800*1360 | 1100 |

| COMLER120KW | COMLER | YCD6Q23H8-210 | 140 | High pressure common rail | Yuchai | 400/230 | 216.5 | 0.8 | 50 | 1500 | 2600*965*1760 | 1200 |

| COMLER150KW | COMLER | YCD6Q33H6-260 | 190 | High pressure common rail | Yuchai | 400/230 | 270.6 | 0.8 | 50 | 1500 | 2600*965*1760 | 1500 |

| COMLER170KW | COMLER | YCD6Q33H6-260 | 190 | High pressure common rail | Yuchai | 400/230 | 306.7 | 0.8 | 50 | 1500 | 2600*965*1760 | 1700 |

| COMLER200KW | COMLER | YCA08350-D30 | 235 | High pressure common rail | Yuchai | 400/230 | 360.9 | 0.8 | 50 | 1500 | 2600*1080*1485 | 1800 |

| COMLER250KW | COMLER | YC6MK420-D30 | 281 | High pressure common rail | Yuchai | 400/230 | 451.1 | 0.8 | 50 | 1500 | 3050*1050*1730 | 2500 |

| COMLER280KW | COMLER | YC6MK450-D30 | 301 | High pressure common rail | Yuchai | 400/230 | 505.2 | 0.8 | 50 | 1500 | 3050*1050*1730 | 2550 |

| COMLER300KW | COMLER | YC6MJ500-D30 | 334 | High pressure common rail | Yuchai | 400/230 | 541.3 | 0.8 | 50 | 1500 | 3150*1150*1730 | 3000 |

| COMLER330KW | COMLER | YC6MJ540-D30 | 365 | High pressure common rail | Yuchai | 400/230 | 595.4 | 0.8 | 50 | 1500 | 3150*1150*1730 | 3200 |

| COMLER360KW | COMLER | YC6MJ600-D30 | 401 | High pressure common rail | Yuchai | 400/230 | 649.5 | 0.8 | 50 | 1500 | 3150*1150*1730 | 3500 |

| COMLER400KW | COMLER | YC6K660-D30 | 441 | High pressure common rail | Yuchai | 400/230 | 721.7 | 0.8 | 50 | 1500 | 3300*1250*1870 | 3800 |

| COMLER500KW | COMLER | YC6TD840-D31 | 561 | Electronic control unit pump | Yuchai | 400/230 | 902.1 | 0.8 | 50 | 1500 | 3800*1680*2100 | 4600 |

| COMLER550KW | COMLER | YC6TD900-D31 | 605 | Electronic control unit pump | Yuchai | 400/230 | 992.3 | 0.8 | 50 | 1500 | 3800*1820*2100 | 4800 |

| COMLER600KW | COMLER | YC6TD1000-D30 | 668 | High pressure common rail | Yuchai | 400/230 | 1082.6 | 0.8 | 50 | 1500 | 3800*1820*2100 | 5400 |

| COMLER650KW | COMLER | YC6TH1070-D31 | 715 | Electronic control unit pump | Yuchai | 400/230 | 1172.8 | 0.8 | 50 | 1500 | 4200*1820*2100 | 6200 |

| COMLER720KW | COMLER | YCDV270A3H-1200 | 800 | Electronic control unit pump | Yuchai | 400/230 | 1299.1 | 0.8 | 50 | 1500 | 4200*1880*2180 | 7400 |

| COMLER800KW | COMLER | YCDV270A3H-1320 | 880 | Electronic control unit pump | Yuchai | 400/230 | 1443.4 | 0.8 | 50 | 1500 | 4200*1880*2180 | 8400 |

| COMLER900KW | COMLER | YC6C1520-D31 | 1016 | Electronic control unit pump | Yuchai | 400/230 | 1623.8 | 0.8 | 50 | 1500 | 4550*1760*2500 | 10600 |

| COMLER1000KW | COMLER | YC6C1660-D31 | 1110 | Electronic control unit pump | Yuchai | 400/230 | 1804.3 | 0.8 | 50 | 1500 | 4650*1760*2500 | 11000 |

| COMLER1100KW | COMLER | YC12VTD1830-D31 | 1220 | Electronic control unit pump | Yuchai | 400/230 | 1984.7 | 0.8 | 50 | 1500 | 4350*2100*2510 | 11500 |

| COMLER1200KW | COMLER | YC12VTD2000-D30 | 1345 | High pressure common rail | Yuchai | 400/230 | 2165.1 | 0.8 | 50 | 1500 | 4350*2100*2510 | 12300 |

| COMLER1350KW | COMLER | YC16VTD2270-D30 | 1520 | High pressure common rail | Yuchai | 400/230 | 2435.8 | 0.8 | 50 | 1500 | 5100*2500*2700 | 14500 |

| COMLER1500KW | COMLER | YC16VTD2510-D30 | 1680 | High pressure common rail | Yuchai | 400/230 | 2706.4 | 0.8 | 50 | 1500 | 5300*2500*2700 | 15000 |

| COMLER1600KW | COMLER | YC16VTD2700-D30 | 1805 | High pressure common rail | Yuchai | 400/230 | 2886.8 | 0.8 | 50 | 1500 | 5300*2500*2700 | 15500 |

| COMLER1800KW | COMLER | YC20VTD3000-D30 | 2005 | High pressure common rail | Yuchai | 400/230 | 3247.7 | 0.8 | 50 | 1500 | 7100*2800*3150 | 18400 |

| COMLER2000KW | COMLER | YC20VTD3300-D30 | 2205 | High pressure common rail | Yuchai | 400/230 | 3608.5 | 0.8 | 50 | 1500 | 7100*2800*3150 | 19400 |

| COMLER2200KW | COMLER | YC16VC3600-D31 | 2405 | Electronic control unit pump | Yuchai | 400/230 | 3969.4 | 0.8 | 50 | 1500 | 6750*2720*3250 | 23400 |

| COMLER2400KW | COMLER | YC16VC4000-D31 | 2673 | Electronic control unit pump | Yuchai | 400/230 | 4330.3 | 0.8 | 50 | 1500 | 7200*2620*3100 | 24000 |

| COMLER2500KW | COMLER | YC16VC4200-D30 | 2808 | High pressure common rail | Yuchai | 400/230 | 4510.7 | 0.8 | 50 | 1500 | 7600*2620*3100 | 25500 |

| COMLER2700KW | COMLER | YC16VC4500-D30 | 3010 | High pressure common rail | Yuchai | 400/230 | 4871.5 | 0.8 | 50 | 1500 | 7800*2620*3100 | 31500 |

| COMLER3000KW | COMLER | YC16VC4900-D30 | 3280 | High pressure common rail | Yuchai | 400/230 | 5412.8 | 0.8 | 50 | 1500 | 7800*2620*3100 | 31500 |

Guangxi Yuchai Marine & Power Machinery Co., Ltd. specializes in the R&D, production, sales, and service of marine engines, power generation engines, gas engines, and related products. Its products are widely used in ships and offshore engineering equipment, power generation, oil drilling, and other fields. Comler has been equipping its diesel generator sets with Yuchai engines in bulk, maintaining a strong cooperative relationship over the years. Yuchai has become one of Comler's key strategic partners for mutual success.

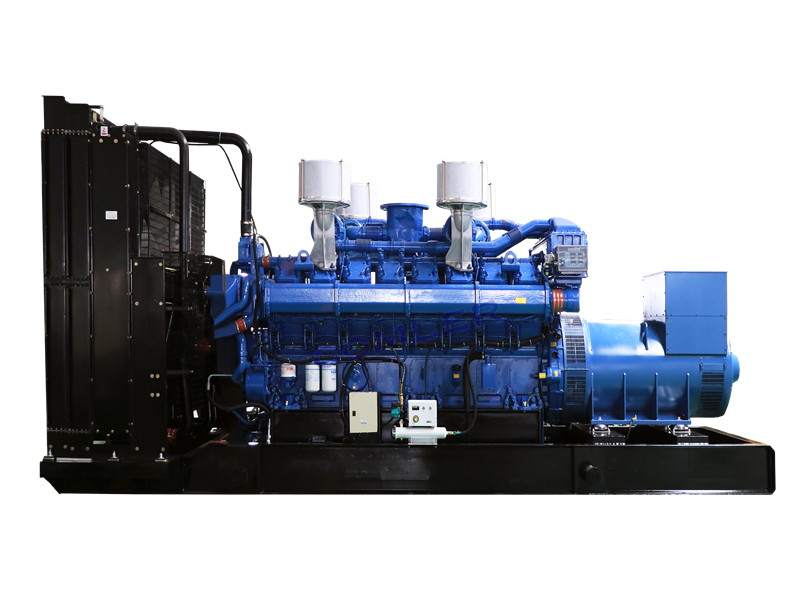

COMLER diesel generator sets integrate high-performance COMLER alternators and Yuchai engines, along with other premium configurations. The advanced integrated design, precision manufacturing, and rigorous assembly processes ensure full compliance with international technical standards. The automatic voltage regulation (AVR) system is meticulously configured according to stringent specifications.

These power generation systems deliver user-friendly operation, enhanced efficiency, reduced fuel consumption (as low as 192g/kWh), extended service life, and eco-friendly performance. Backed by a comprehensive pre-sales, in-sales, after-sales and maintenance-oriented service network, COMLER maintains its premium brand commitment to delivering exceptional customer support.

As an industry leader, COMLER actively contributes to technological innovation and advancement in China's electromechanical engineering sector, driving progress in power generation solutions.

鲁公网安备37083002370842号

鲁公网安备37083002370842号