SDEC series (10kw-2500kw)Technical Specifications:

| Model | Brand | Engine Model | Engine Normal Power (KW) | Speed Control | Engine Brand | Rated voltage (V) | Rated current (A) | Power factor | Frequency (HZ) | Speed (r/min) | Dimensions (mm) | Weight (KG) |

| COMLER10KW | COMLER | 4Z2.9-G43 | 16 | High pressure common rail | SDEC | 400/230 | 18 | 0.8 | 50 | 1500 | 1400*600*1005 | 470 |

| COMLER15KW | COMLER | 4Z2.9-G42 | 22 | High pressure common rail | SDEC | 400/230 | 27.1 | 0.8 | 50 | 1500 | 1400*600*1005 | 475 |

| COMLER20KW | COMLER | 4Z2.9-G41 | 27 | High pressure common rail | SDEC | 400/230 | 36.1 | 0.8 | 50 | 1500 | 1400*600*1005 | 480 |

| COMLER30KW | COMLER | 4Z3.2-G41 | 36 | High pressure common rail | SDEC | 400/230 | 54.1 | 0.8 | 50 | 1500 | 1440*600*1050 | 500 |

| COMLER40KW | COMLER | 4ZTAA3.2-G32 | 49 | High pressure common rail | SDEC | 400/230 | 72.2 | 0.8 | 50 | 1500 | 1700*750*1180 | 950 |

| COMLER50KW | COMLER | 4ZTAA3.2-G34 | 58 | High pressure common rail | SDEC | 400/230 | 90.2 | 0.8 | 50 | 1500 | 1700*750*1180 | 1050 |

| COMLER70KW | COMLER | 4HTAA4.3-G33 | 78 | High pressure common rail | SDEC | 400/230 | 126.3 | 0.8 | 50 | 1500 | 1900*800*1420 | 1250 |

| COMLER80KW | COMLER | 4HTAA4.3-G34 | 95 | High pressure common rail | SDEC | 400/230 | 144.3 | 0.8 | 50 | 1500 | 1900*800*1420 | 1280 |

| COMLER100KW | COMLER | 4HTAA4.3-G36 | 125 | High pressure common rail | SDEC | 400/230 | 180.4 | 0.8 | 50 | 1500 | 2050*800*1450 | 1350 |

| COMLER120KW | COMLER | 6HTAA6.5-G32 | 140 | High pressure common rail | SDEC | 400/230 | 216.5 | 0.8 | 50 | 1500 | 2600*900*1550 | 1600 |

| COMLER150KW | COMLER | 6HTAA6.5-G34 | 186 | High pressure common rail | SDEC | 400/230 | 270.6 | 0.8 | 50 | 1500 | 2600*900*1550 | 1800 |

| COMLER170KW | COMLER | 6HTAA6.5-G34 | 186 | High pressure common rail | SDEC | 400/230 | 306.7 | 0.8 | 50 | 1500 | 2600*900*1550 | 2030 |

| COMLER180KW | COMLER | 6DTAA8.9-G32 | 208 | High pressure common rail | SDEC | 400/230 | 324.8 | 0.8 | 50 | 1500 | 2600*960*1650 | 2300 |

| COMLER200KW | COMLER | 6DTAA8.9-G33 | 230 | High pressure common rail | SDEC | 400/230 | 360.9 | 0.8 | 50 | 1500 | 2600*960*1650 | 2600 |

| COMLER230KW | COMLER | 6DTAA8.9-G34 | 255 | High pressure common rail | SDEC | 400/230 | 415 | 0.8 | 50 | 1500 | 2600*960*1650 | 2800 |

| COMLER250KW | COMLER | 6ETAA11.8-G33 | 307 | High pressure common rail | SDEC | 400/230 | 451.1 | 0.8 | 50 | 1500 | 3150*1140*1760 | 3100 |

| COMLER280KW | COMLER | 6ETAA11.8-G33 | 307 | High pressure common rail | SDEC | 400/230 | 505.2 | 0.8 | 50 | 1500 | 3150*1140*1760 | 3200 |

| COMLER300KW | COMLER | 6ETAA11.8-G31 | 340 | High pressure common rail | SDEC | 400/230 | 541.3 | 0.8 | 50 | 1500 | 3150*1140*1760 | 3300 |

| COMLER320KW | COMLER | 6ETAA12.8-G32 | 360 | High pressure common rail | SDEC | 400/230 | 577.4 | 0.8 | 50 | 1500 | 3150*1230*1760 | 3500 |

| COMLER360KW | COMLER | 6ETAA12.8-G31 | 401 | High pressure common rail | SDEC | 400/230 | 649.5 | 0.8 | 50 | 1500 | 3150*1230*1760 | 3600 |

| COMLER400KW | COMLER | 6ETAA12.8-G310 | 450 | High pressure common rail | SDEC | 400/230 | 721.7 | 0.8 | 50 | 1500 | 3150*1230*1760 | 3800 |

| COMLER450KW | COMLER | 6KTAA25-G35 | 520 | High pressure common rail | SDEC | 400/230 | 811.9 | 0.8 | 50 | 1500 | 3800*1240*2356 | 5050 |

| COMLER500KW | COMLER | 6KTAA25-G34 | 572 | High pressure common rail | SDEC | 400/230 | 902.1 | 0.8 | 50 | 1500 | 3800*1240*2356 | 5200 |

| COMLER550KW | COMLER | 6KTAA25-G33 | 622 | High pressure common rail | SDEC | 400/230 | 992.3 | 0.8 | 50 | 1500 | 3800*1240*2356 | 5400 |

| COMLER600KW | COMLER | 6KTAA25-G32 | 685 | High pressure common rail | SDEC | 400/230 | 1082.6 | 0.8 | 50 | 1500 | 3800*1240*2356 | 5600 |

| COMLER660KW | COMLER | 6KTAA25-G31 | 728 | High pressure common rail | SDEC | 400/230 | 1190.8 | 0.8 | 50 | 1500 | 3800*1240*2356 | 6050 |

| COMLER730KW | COMLER | 6KTAA25-G320 | 820 | High pressure common rail | SDEC | 400/230 | 1317.1 | 0.8 | 50 | 1500 | 4100*1800*2450 | 7500 |

| COMLER800KW | COMLER | 6KTAA25-G321 | 880 | High pressure common rail | SDEC | 400/230 | 1443.4 | 0.8 | 50 | 1500 | 4100*1800*2450 | 8200 |

| COMLER900KW | COMLER | 6WTAA35-G310 | 1018 | Electronic control unit pump | SDEC | 400/230 | 1623.8 | 0.8 | 50 | 1500 | 4450*1800*2430 | 10500 |

| COMLER1000KW | COMLER | 6WTAA35-G311 | 1118 | Electronic control unit pump | SDEC | 400/230 | 1804.3 | 0.8 | 50 | 1500 | 4450*1850*2430 | 11000 |

| COMLER1100KW | COMLER | 6WTAA35-G313 | 1230 | Electronic control unit pump | SDEC | 400/230 | 1984.7 | 0.8 | 50 | 1500 | 4450*1850*2430 | 11600 |

| COMLER1200KW | COMLER | 12KTA58-G35 | 1420 | High pressure common rail | SDEC | 400/230 | 2165.1 | 0.8 | 50 | 1500 | 5250*2320*2834 | 13800 |

| COMLER1350KW | COMLER | 12KTA58-G34 | 1560 | High pressure common rail | SDEC | 400/230 | 2435.8 | 0.8 | 50 | 1500 | 5250*2320*2834 | 14000 |

| COMLER1500KW | COMLER | 12KTA58-G33 | 1720 | High pressure common rail | SDEC | 400/230 | 2706.4 | 0.8 | 50 | 1500 | 5400*2320*2834 | 16000 |

| COMLER1600KW | COMLER | 12KTA58-G32 | 1850 | High pressure common rail | SDEC | 400/230 | 2886.8 | 0.8 | 50 | 1500 | 5400*2320*2834 | 16500 |

| COMLER1800KW | COMLER | 12KTA58-G31 | 2010 | High pressure common rail | SDEC | 400/230 | 3247.7 | 0.8 | 50 | 1500 | 5500*2320*2900 | 18500 |

| COMLER2000KW | COMLER | 16KTA76-G33 | 2250 | High pressure common rail | SDEC | 400/230 | 3608.5 | 0.8 | 50 | 1500 | 6500*2350*2845 | 21800 |

| COMLER2200KW | COMLER | 16KTA76-G32 | 2510 | High pressure common rail | SDEC | 400/230 | 3969.4 | 0.8 | 50 | 1500 | 6500*2350*2845 | 22800 |

| COMLER2400KW | COMLER | 16KTA76-G31 | 2680 | High pressure common rail | SDEC | 400/230 | 4330.3 | 0.8 | 50 | 1500 | 6500*2350*2845 | 24800 |

| COMLER2500KW | COMLER | 16KTA76-G310 | 2773 | High pressure common rail | SDEC | 400/230 | 4510.7 | 0.8 | 50 | 1500 | 6500*2350*2845 | 25800 |

Shanghai New Power Automotive Technology Co., Ltd. (formerly known as Shanghai Diesel Engine Co., Ltd.), established in 1947 and now a subsidiary of SAIC Motor, is located on the scenic banks of the Huangpu River. Over its 70-year development journey, the company has earned a global reputation for exceptional quality and comprehensive service, becoming one of the strategic partners of COMLER.

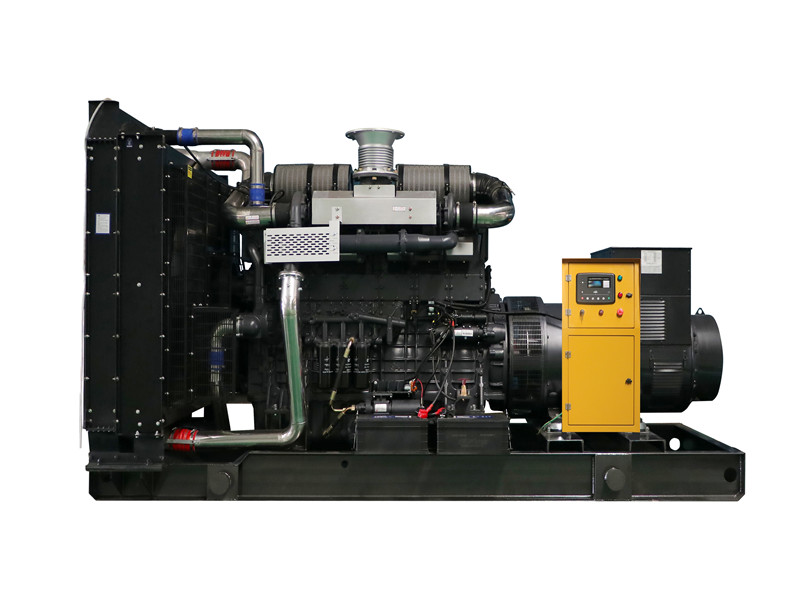

Comler diesel generator sets using high-performance COMLER generator, Shangchai engine and other configurations, superior overall design, production, assembly more in line with standard technical requirements. Constant pressure control system, are configured according to standard requirements. With more convenient operation and use, good efficiency, lower fuel consumption, longer service life, low-carbon environmental protection and other characteristics. Perfect pre-sale, sale, after-sale and maintenance service system, respected brand, will provide customers with better service, to promote China's electromechanical industry to contribute to the overall technological development and progress.

鲁公网安备37083002370842号

鲁公网安备37083002370842号