Perkins series (10kw-20000kw)Technical Specifications

| Model | Brand | Engine Model | Engine Normal Power (KW) | Speed Control | Engine Brand | Rated voltage (V) | Rated current (A) | Power factor | Frequency (HZ) | Speed (r/min) | Dimensions (mm) | Weight (KG) |

| COMLER10KW | COMLER | 403A-15G1 | 13.5 | Mechanical Governing | Perkins | 400/230 | 18 | 0.8 | 50 | 1500 | 1400*600*950 | 450 |

| COMLER16KW | COMLER | 404A-22G1 | 20.6 | Mechanical Governing | Perkins | 400/230 | 28.9 | 0.8 | 50 | 1500 | 1400*600*950 | 480 |

| COMLER22KW | COMLER | 404D-22TG | 27.7 | Electronic Governing | Perkins | 400/230 | 39.7 | 0.8 | 50 | 1500 | 1400*600*950 | 500 |

| COMLER50KW | COMLER | 1104D-44TG2 | 57.6 | Electronic Governing | Perkins | 400/230 | 90.2 | 0.8 | 50 | 1500 | 1900*800*1270 | 600 |

| COMLER64KW | COMLER | 1104D-E44TAG1 | 85.7 | Electronic Fuel Injection | Perkins | 400/230 | 115.5 | 0.8 | 50 | 1500 | 1900*800*1370 | 800 |

| COMLER80KW | COMLER | 1104D-E44TAG2 | 94.6 | Electronic Fuel Injection | Perkins | 400/230 | 144.3 | 0.8 | 50 | 1500 | 1900*800*1370 | 900 |

| COMLER110KW | COMLER | 1106D-E70TAG2 | 149.4 | Electronic Fuel Injection | Perkins | 400/230 | 198.5 | 0.8 | 50 | 1500 | 2300*900*1450 | 1200 |

| COMLER120KW | COMLER | 1106D-E70TAG3 | 162.9 | Electronic Fuel Injection | Perkins | 400/230 | 216.5 | 0.8 | 50 | 1500 | 2300*900*1450 | 1260 |

| COMLER150KW | COMLER | 1106D-E70TAG4 | 188.7 | Electronic Fuel Injection | Perkins | 400/230 | 270.6 | 0.8 | 50 | 1500 | 2450*900*1450 | 1450 |

| COMLER160KW | COMLER | 1206D-E70TTAG1 | 204.9 | Electronic Fuel Injection | Perkins | 400/230 | 288.7 | 0.8 | 50 | 1500 | 2600*950*1850 | 1600 |

| COMLER180KW | COMLER | 1206D-E70TTAG2 | 226.8 | Electronic Fuel Injection | Perkins | 400/230 | 324.8 | 0.8 | 50 | 1500 | 2600*950*1850 | 1780 |

| COMLER200KW | COMLER | 1206D-E70TTAG3 | 248.5 | Electronic Fuel Injection | Perkins | 400/230 | 360.9 | 0.8 | 50 | 1500 | 2600*950*1850 | 2000 |

| COMLER250KW | COMLER | 1706A-E93TAG1 | 295 | Electronic Fuel Injection | Perkins | 400/230 | 451.1 | 0.8 | 50 | 1500 | 3150*1140*1700 | 2600 |

| COMLER280KW | COMLER | 2206C-E13TAG2 | 305 | Electronic Fuel Injection | Perkins | 400/230 | 505.2 | 0.8 | 50 | 1500 | 3300*1250*2100 | 3000 |

| COMLER320KW | COMLER | 2206D-E13TAG3 | 349 | Electronic Fuel Injection | Perkins | 400/230 | 577.4 | 0.8 | 50 | 1500 | 3300*1250*2100 | 3100 |

| COMLER360KW | COMLER | 2506C-E15TAG1 | 434 | Electronic Fuel Injection | Perkins | 400/230 | 649.5 | 0.8 | 50 | 1500 | 3300*1250*2100 | 3500 |

| COMLER400KW | COMLER | 2506D-E15TAG2 | 435 | Electronic Fuel Injection | Perkins | 400/230 | 721.7 | 0.8 | 50 | 1500 | 3300*1250*2100 | 4500 |

| COMLER500KW | COMLER | 2806C-E18TAG1A | 514 | Electronic Fuel Injection | Perkins | 400/230 | 902.1 | 0.8 | 50 | 1500 | 3700*1465*2120 | 5400 |

| COMLER640KW | COMLER | 4006-23TAG3A | 705 | Electronic Governing | Perkins | 400/230 | 1154.7 | 0.8 | 50 | 1500 | 3800*1700*2356 | 6500 |

| COMLER720KW | COMLER | 4008TAG1A | 805 | Electronic Governing | Perkins | 400/230 | 1299.1 | 0.8 | 50 | 1500 | 4550*2150*2380 | 7500 |

| COMLER820KW | COMLER | 4008TAG2A | 899 | Electronic Governing | Perkins | 400/230 | 1479.5 | 0.8 | 50 | 1500 | 4550*2150*2380 | 8500 |

| COMLER900KW | COMLER | 4008-30TAG3 | 1105 | Electronic Governing | Perkins | 400/230 | 1623.8 | 0.8 | 50 | 1500 | 4550*2150*2380 | 9500 |

| COMLER1000KW | COMLER | 4012-46TWG2A | 1113 | Electronic Governing | Perkins | 400/230 | 1804.3 | 0.8 | 50 | 1500 | 4650*1980*2480 | 11500 |

| COMLER1200KW | COMLER | 4012-46TAG2A | 1500 | Electronic Governing | Perkins | 400/230 | 2165.1 | 0.8 | 50 | 1500 | 4800*2115*2605 | 13000 |

| COMLER1350KW | COMLER | 4012-46TAG3A | 1521 | Electronic Governing | Perkins | 400/230 | 2435.8 | 0.8 | 50 | 1500 | 4800*2115*2605 | 13500 |

| COMLER1500KW | COMLER | 4016TAG1A | 1588 | Electronic Governing | Perkins | 400/230 | 2706.4 | 0.8 | 50 | 1500 | 5950*2140*2690 | 16500 |

| COMLER1600KW | COMLER | 4016TAG2A | 1766 | Electronic Governing | Perkins | 400/230 | 2886.8 | 0.8 | 50 | 1500 | 5950*2140*2690 | 18500 |

| COMLER1800KW | COMLER | 4016-61TRG3 | 1975 | Electronic Governing | Perkins | 400/230 | 3247.7 | 0.8 | 50 | 1500 | 6150*2200*2690 | 20400 |

| COMLER2000KW | COMLER | 4016-61TRG3X | 2183 | Electronic Governing | Perkins | 400/230 | 3608.5 | 0.8 | 50 | 1500 | 6150*2200*2690 | 21400 |

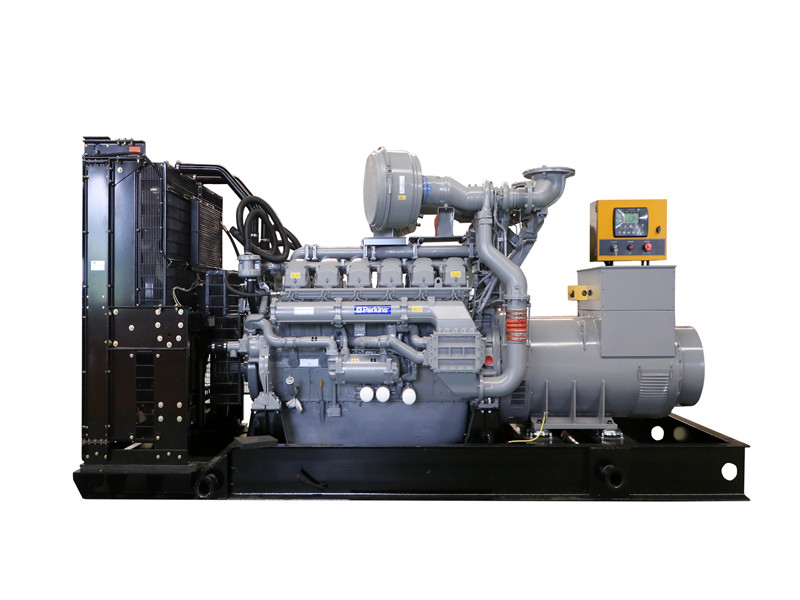

Perkins Engines, a UK-based company founded in 1932 by British entrepreneur Frank Perkins in Peterborough, England, is a global leader in the production of off-highway diesel and natural gas engines with a power range from 4KW to 2000KW. With an extensive service network spanning over 180 countries and regions and supported by 3,500 service outlets, Perkins ensures that customers worldwide receive consistent, high-standard technical support. All service centers adhere to stringent quality benchmarks, guaranteeing exceptional service no matter where the customer is located.The strategic partnership between Perkins and Comler has established Perkins engines as the preferred power source for Comler's premium generator sets. For years, this collaboration has delivered top-tier products and services to high-end clients across various industries.

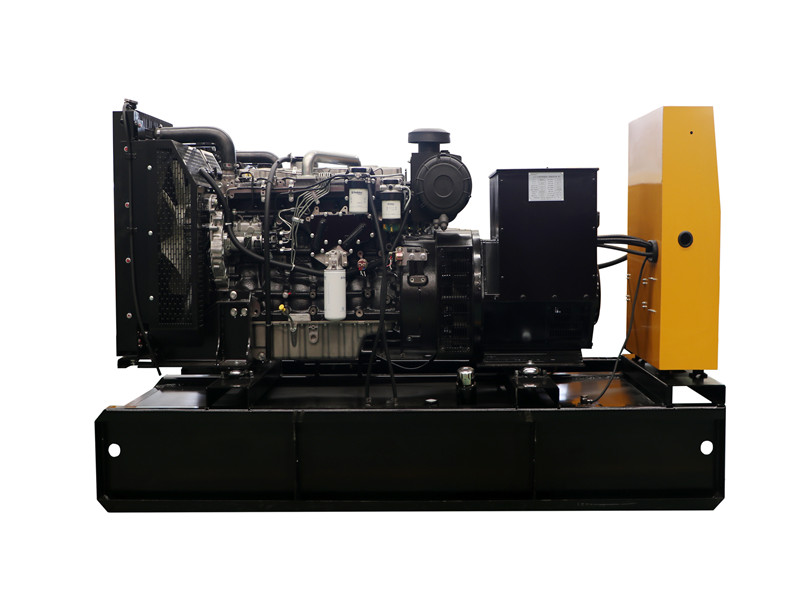

Comler Diesel Generator Sets integrate high-performance COMLER generators and Perkins engines, among other premium components. The advanced design, precision manufacturing, and rigorous assembly processes ensure compliance with the highest technical standards. Equipped with precision voltage regulation systems and configured to meet stringent requirements, these generator sets offer user-friendly operation, superior efficiency, reduced fuel consumption, extended lifespan, and eco-friendly performance.Our backed by a comprehensive pre-sales, sales, after-sales, and maintenance service system, along with a prestigious brand reputation, Comler is committed to delivering unparalleled service to its customers. This dedication not only enhances user experience but also drives the technological advancement of China's electromechanical industry.

鲁公网安备37083002370842号

鲁公网安备37083002370842号